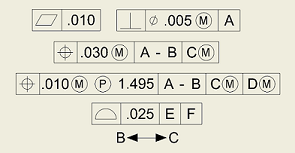

GD&T SERVICES BY ENGINEERING 2 PRODUCTION, INCWhat E2P can do for your GD&T project! E2P takes your legacy drawings with outdated GD&T and apply our knowledge, understanding, and advanced techniques to bring your engineering drawings up current with the latest standards. We analyze each part and mating component to maximize tolerance zones enabling a greater number of product acceptances. E2P's many years of experience in Product Design, Manufacturing, and Inspection, has provided a perspective that enables us to apply GD&T to you specific project. What is GD&T?

GD&T is a language used on engineering drawings to define the allowable deviation from perfection for features on a manufactured part. Like any language, GD&T's proper use requires competent understanding and application. GD&T focuses on Feature Functionality and Tolerance Zone Sizes & Locations. The engineering drawing language of GD&T is the key link between members of the design team and the manufacturing team. GD&T's proper use is an efficient tool that allows Designers and Engineers to clearly communicate functional design requirements for a given feature of a piece part. This eliminates wasted effort and materials by permitting team members responsible for Purchasing, Manufacturing, and Quality to operate more independently and efficiently within larger tolerance zones for product acceptance. Who Uses GD&T? GD&T is used by Designers and Engineers who create and use engineering drawings. Applied properly, manufacturing and inspection cost can be reduced as the result of improved communication between the functions of Design, Manufacturing, and Inspection.

|